Frequent error pattern

Outgassing during powder coating

Powder coating is a process for coating the surface of materials. Dry powder is applied to a substrate and then baked at an elevated temperature to create a durable coating. Outgassing is a potential problem, along with other possible defects in the coating process, which can lead to unsightly defects in the coating and also impair the benefits of the coating.

What is outgassing?

During outgassing, gaseous compounds are released during the heating process of the workpiece coated with powder coating. These gas emissions can have various causes and can be responsible for a reduction in the quality and durability of the coating.

Causes:

Certain materials in the substrate or in the coating powder can vaporise or decompose at high temperatures, releasing gases in the process. Hot-dip galvanised steel in particular is prone to outgassing during the paint baking process.

Residual moisture in the substrate or in the coating powder can vaporise during the heating process and produce gaseous compounds.

Foreign particles or impurities in the coating powder or on the surface of the substrate can outgas at high temperatures.

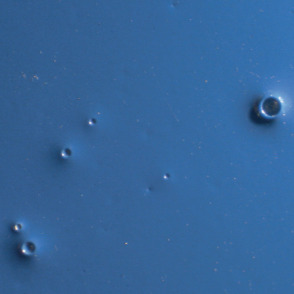

Outgassing during powder coating can lead to various blemishes. On the one hand, these are visible as visual defects in the form of bubbles or

small craters; on the other hand, corrosion protection is also reduced in the affected areas.

Minimise outgassing during powder coating

Outgassing can lead to various blemishes. On the one hand, these are visible as visual defects in the form of bubbles or small craters; on the other hand, corrosion protection is also reduced in the affected areas.

Thorough preparation

Thorough cleaning and preparation of the substrates to be coated helps to remove potential sources of outgassing. Processes such as degreasing, pickling and phosphating remove surface and organic contaminants that could otherwise cause outgassing during coating. Condensation on the surface is prevented by appropriate acclimatisation before the paint is applied.

Material properties

The right choice of coating materials and processes is also essential. The powders used should have a low content of volatile organic compounds. Suitable binder systems help to reduce the emission of gases during the coating and curing process.

Choice of coating process

Coating processes such as low-temperature powder coating reduce the risk of outgassing.

Tempering

Before the actual firing process, tempering the powder-coated objects helps to prevent gases from escaping.

Stoving temperature and time

It makes sense to optimise the process parameters in order to avoid gas formation. The risk of outgassing is minimised by correctly setting the curing temperature and time while selecting the ideal powder coating.

Repair of damage caused by outgassing in the powder coating

Repairing damage caused by outgassing in powder coatings requires specialist knowledge, especially for complex or large surfaces. Firstly, the affected area must be extensively cleaned and sanded down. This ensures that the subsequent powder coating application adheres well and guarantees an optimum finish.

Small damaged areas in interior applications can be repaired with special touch-up pencils, while minor scratches in exterior applications can be repaired with a two-component paint. In the case of damage that extends to the metal substrate, a new primer coat is required in order to achieve optimum corrosion protection and a durable repair.

Optimum powder coatings with FreiLacquers

FreiLacke’s product portfolio includes a large selection of powder coatings for a wide variety of applications. Whether for steel and light alloy wheels, where appearance also plays a major role, for wood-based materials, plastics or for products in the sanitary sector – as experts in coating solutions, we have the right powder coatings in a wide range of colours for your project.

Our powder coatings not only ensure an optimum finish, they are also economical. They enable material utilisation of up to 99 %. In addition, our powder coatings are chemically and mechanically resistant on many substrates and in a wide variety of application environments.

Another advantage of our powder coatings is that they do not contain any solvents and are therefore harmless to health and environmentally friendly – as confirmed by EMAS certification since 1996.

Discover our powder coating solutions

Cost-efficient, environmentally friendly and highly durable.

We are not only the right contact for powder coatings, but also for coating solutions of all kinds for a wide range of industries. Whether vertical or horizontal system coatings, electrocoatings or industrial coatings – the quality coatings from FreiLacke are high-performance.