Powder coatings for the high-tech working environment

of the future

FreiLacke develops innovative solution for clean room and ESD applications

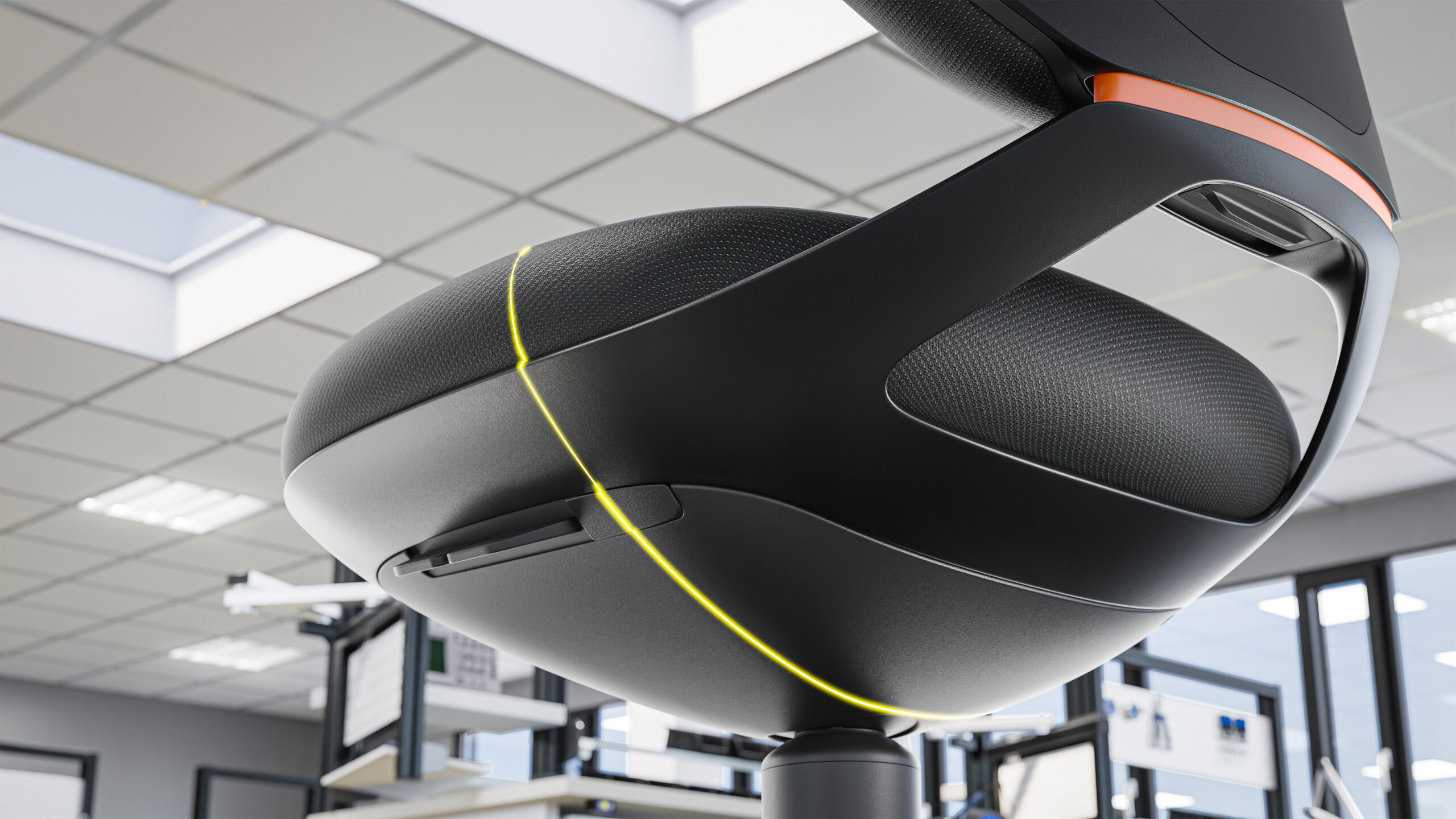

The new Bimos brand “TEXON” work chair from Interstuhl designed for environments like clean rooms, laboratories and ESD areas has recently been launched on the market. This chair meets stringent requirements on function, hygiene and durability. A proprietary powder coating developed by FreiLacke which also meets technical and design specifications plays a crucial role here.

Special products require special manufacturing conditions. This applies primarily in research, optics/laser technology, aerospace technology and other high-tech industries. For the most part, these conditions can only be created in laboratories or clean rooms where the air is kept free of dust and micro-organisms by filtration systems. Other items require ESD conditions, i.e. protected areas in which static electricity discharges are controlled so as to protect sensitive components from damage or destruction.

These kinds of complex working environments place the most stringent requirements on safety, ergonomics and hygiene – requirements which also apply for inventory and furnishings. With the “TEXON”, there is now a Bimos brand chair on the market which not only meets clean room conditions, but also collected several important design prizes when it launched.

Focusing on function and resistance

Interstuhl, a family-operated company located in the Swiss Alps, have been developing and building chairs for working environments for six decades. Their Bimos brand has specialised in work chairs for production, ESD areas, laboratories and clean rooms. The chair bases, chair frames and chair backrests of the new “TEXON” work chair are made of die-cast aluminium and steel. As specified by the designers and product managers, these components should be given a metal look in the colours white aluminium and black grey. As for technical composition, Interstuhl chose powder coating so as to maximise both function and the resistance of surfaces. A wet coating like the one used for prototyping would only be an emergency solution for the technical team, as it wouldn’t have exhibited the desired level of quality.

A suitable coating solution which would also meet the clean room and ESD coating requirements was needed. As Interstuhl have had an excellent cooperative relationship with FreiLacke – also a family-operated company – for many years, the request went straight to the Black Forest coatings experts. They knew what FreiLacke were capable of. As well, several employees had already undergone training in Döggingen, according to the company.

High resistance to cleaning and disinfecting agents required

According to Ralf Kerner of FreiLacke industry sales, development of the powder coating was quite challenging: “The components were coated with liquid coatings for sampling purposes and now had to be given the same surfaces with a powder coating. The powder coatings also had to be configured for die-cast aluminium and its outgassing characteristics.” Due to the areas of use – clean rooms, ESD, laboratories and in production – a whole host of other characteristics were also required, such as a conductive property in accordance with DIN EN IEC 61340-5-1, a highly wear-resistant surface and high resistance to very aggressive cleaning and disinfecting agents in some cases. As well, there was no tolerance whatsoever with regard to effect formation and surface composition. “Our service is offering our customers application solutions, even if they’re challenging and multifaceted as was the case here”, said Kerner.

The look and feel of a metal surface

The developers at FreiLacke were able to create a powder coating surface based on polyester resin with the look and feel of a matt metal surface. Development lasted round a year and included several readjustments, as there were initially some problems with the application behaviour of white aluminium. FreiLacke modified the coating in several steps at their own laboratory until the texture was entirely convincing.

The FREIOTHERM PP5151OI1384 powder coating in white aluminium and FREIOTHERM PP5061NRA721 in black grey impressed with their surface hardness and mechanical resistance and stayed put on the degassing substrate as well. The high-tech coatings are applied with Corona guns and are easy to process, with a layer thickness of round 60–80 μm recommended by FreiLacke. According to the chair manufacturer, they were very well advised regarding the powder for the new TEXON flagship chair and the level of commitment and dedication of the FreiLacke team was very high.

Awarded a prize at its premier

When the high-tech chair was unveiled at the Orgatec 2024 trade fair, it also caused quite a stir. The TEXON received the gold 2025 German Design Award for its outstanding product design. Gold is the highest attainable level of this award and is only granted to products which serve as trailblazers for entire industries. The gold distinction highlights the innovativeness and optimal design quality of the TEXON and sets a high standard for the future of ergonomic working.

The chair was also declared winner of the German Innovation Award in the #W2 category, “Excellence in Business to Business – Machines & Engineering”. The panel concluded that the TEXON met the challenges of complex working environments thanks to its combination of auto-motion technology for dynamic sitting, ESD-compliant features and a hygienically optimised design.

A small, but crucial, part of this was likely thanks to the newly developed powder coatings. With this, the FreiLacke team were able to impressively demonstrate that they are already well equipped for the working environments of tomorrow, today.